Brewing Equipment

Your Product & Your Production Goals

Some of our clients are seasoned experts in the creation of beer and the oversight of a mature production facility, and they use BrewStar Systems for sourcing the best quality equipment and peripheral components.

Other clients desire a more consultative approach, starting with an idea and a blank piece of paper. We can guide you from the very beginning on how to identify the correct brewery size, layout, and design for your business, taking you all the way through to installation, commissioning, and that celebratory completion beer.

Here is an example of some of the considerations that we will discuss with you:

What are your monthly and annual production goals? What is your budget? What is the size and nature of your location? What types of beer are your producing? What is the volume range for each batch? What are your staff resources? What is your workable production floor space? What are your wider overall premises needs and deliverables? Is this phase one in a longer-term business growth objective?

If you don’t know the answers to some of these questions yet, don’t worry. That’s what we are here to help with. Breweries might be hard work, but the best thought-out ones do work, and result in healthy businesses.

Budget, Layout & Space

The correct layout of your brewery makes a big impact on your business efficiency, the quality of your beer, and the vibe of your venue. There are many things that we take into account, but here are three of our top priorities.

01. Cost Reduction

Process management and a diligent brewery design allows for a healthy cumulative effect of cost-reduction over time, identifying improvements in workflows and an efficient selection when it comes to your equipment order.

Avoiding redundant tasks, correct economics of tank size and location, pre-empting future equipment additions, and ensuring best tank placement to minimise beer line cooling and insulation. These are just some of the ways we work to identify cost savings for your project.

02. Quality & Cleanliness

We build the ease of cleaning aspects into your overall design layout from the start. What is the most efficient placement of equipment in each room, and the best methods of CIP for each application?

A production facility that is designed to be cleaned quickly, easily, and effectively will be free of contamination, and this will save your business time and money whilst ensuring product quality.

03. Energy Efficiency

Our consultation will consider your individual circumstances and energy goals. Such as:

How can we decrease the distance between your production steps to reduce pumping requirements? Can we build in heat recovery and distribution systems within your floor plan? Can the proximity of your utility and tank placements minimise piping costs and energy loss?

Let’s talk energy conservation for a greener brewery and a reduction in your energy costs.

Now things are getting exciting

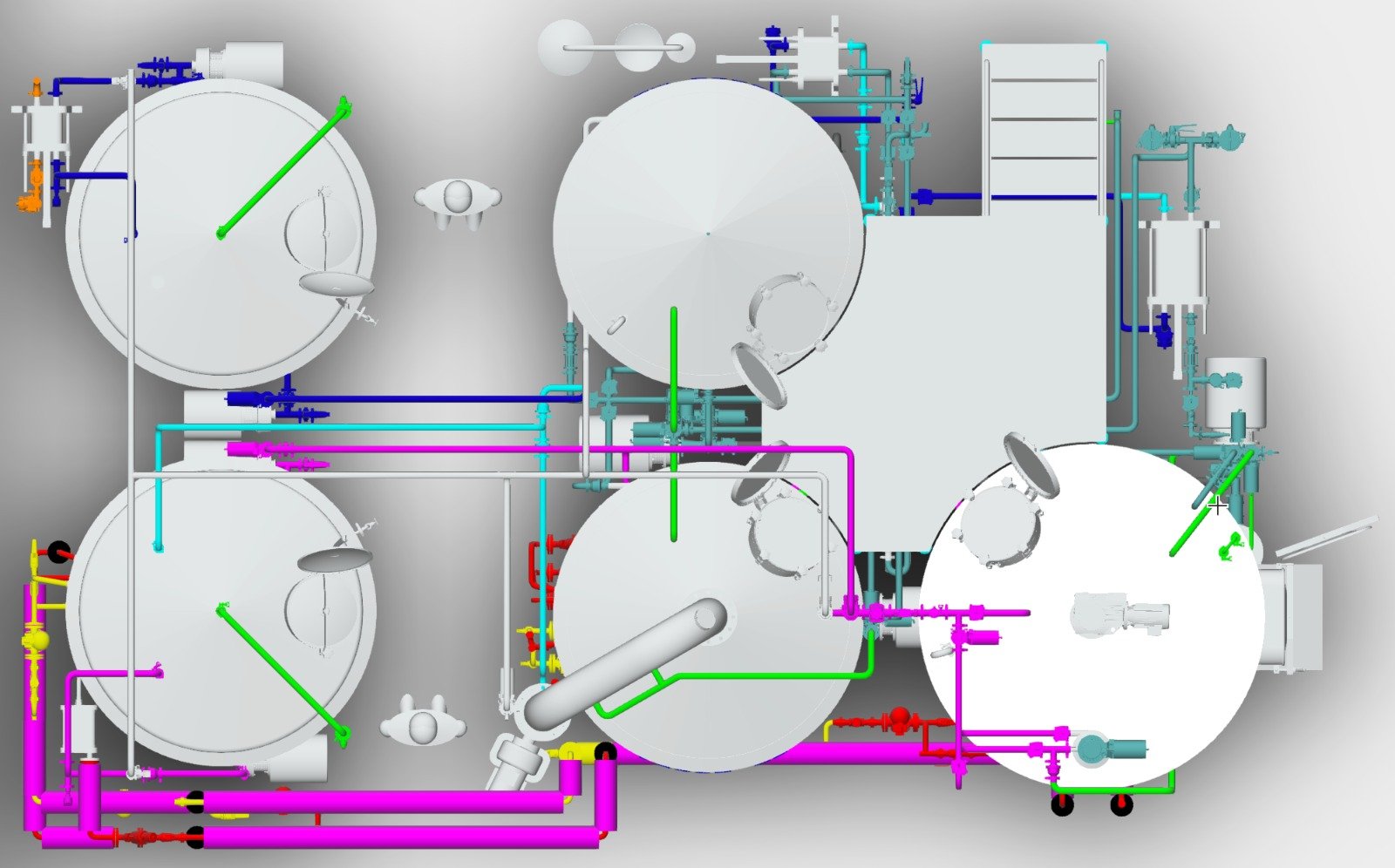

Manufacturing & Installation

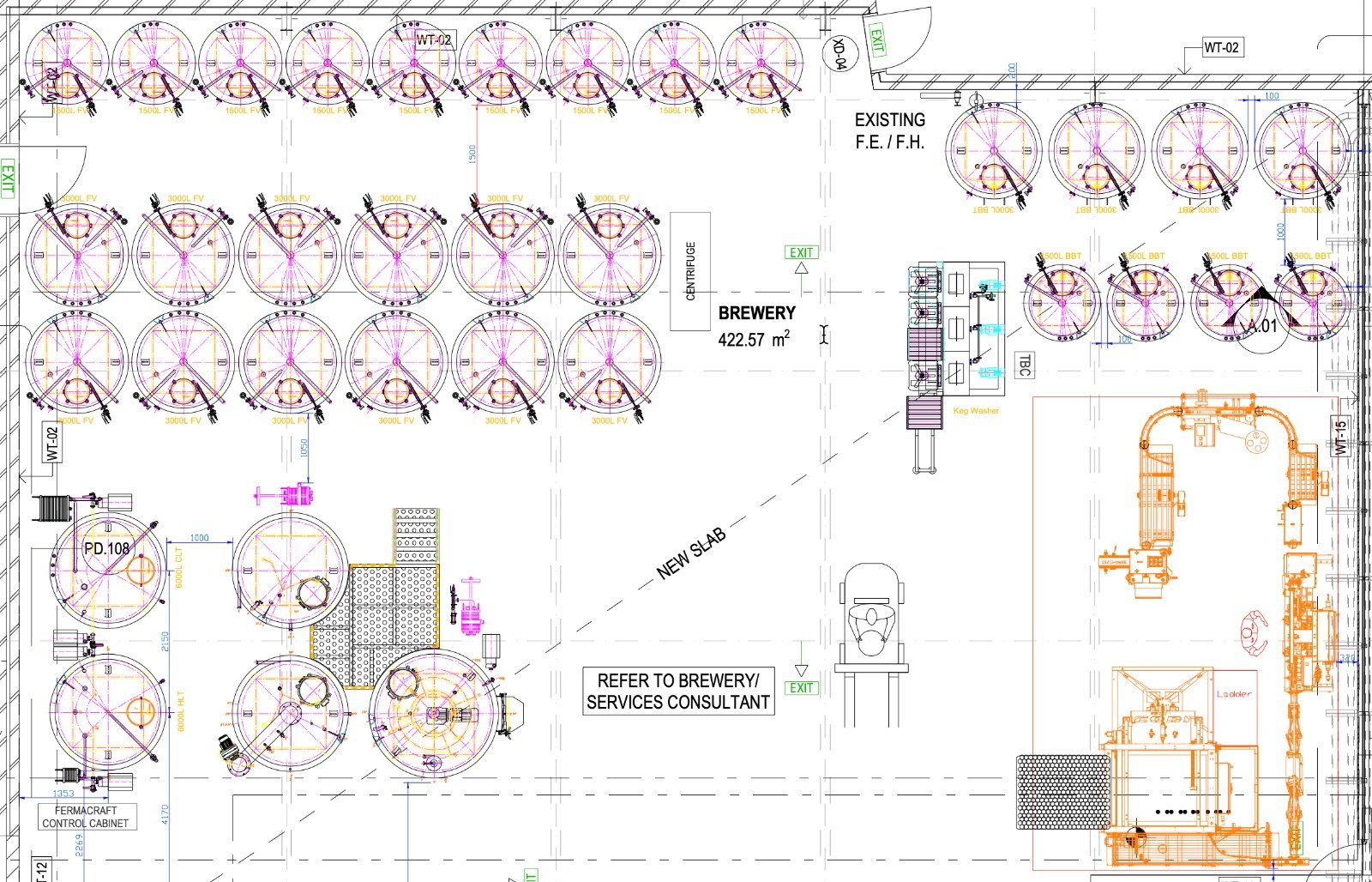

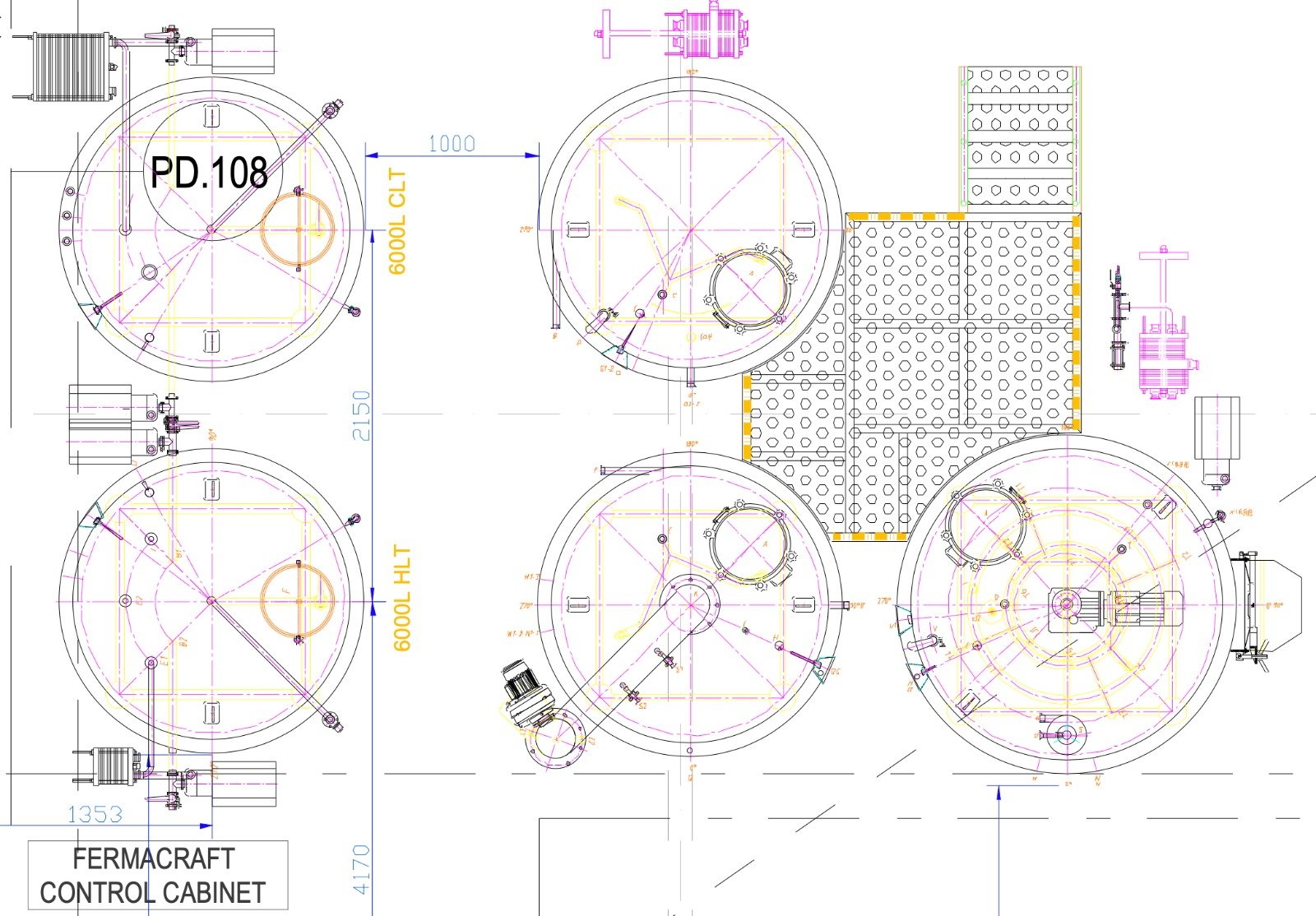

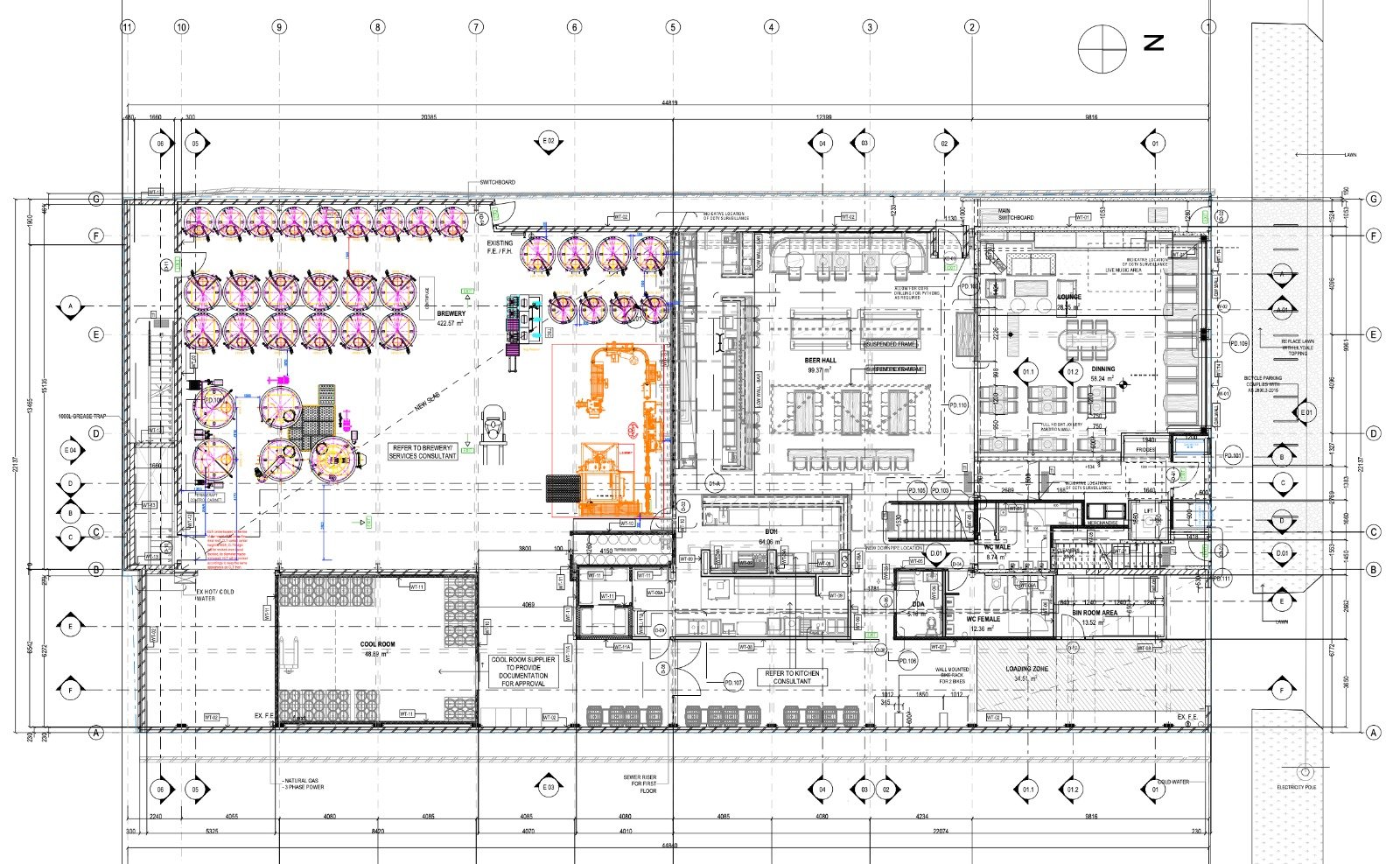

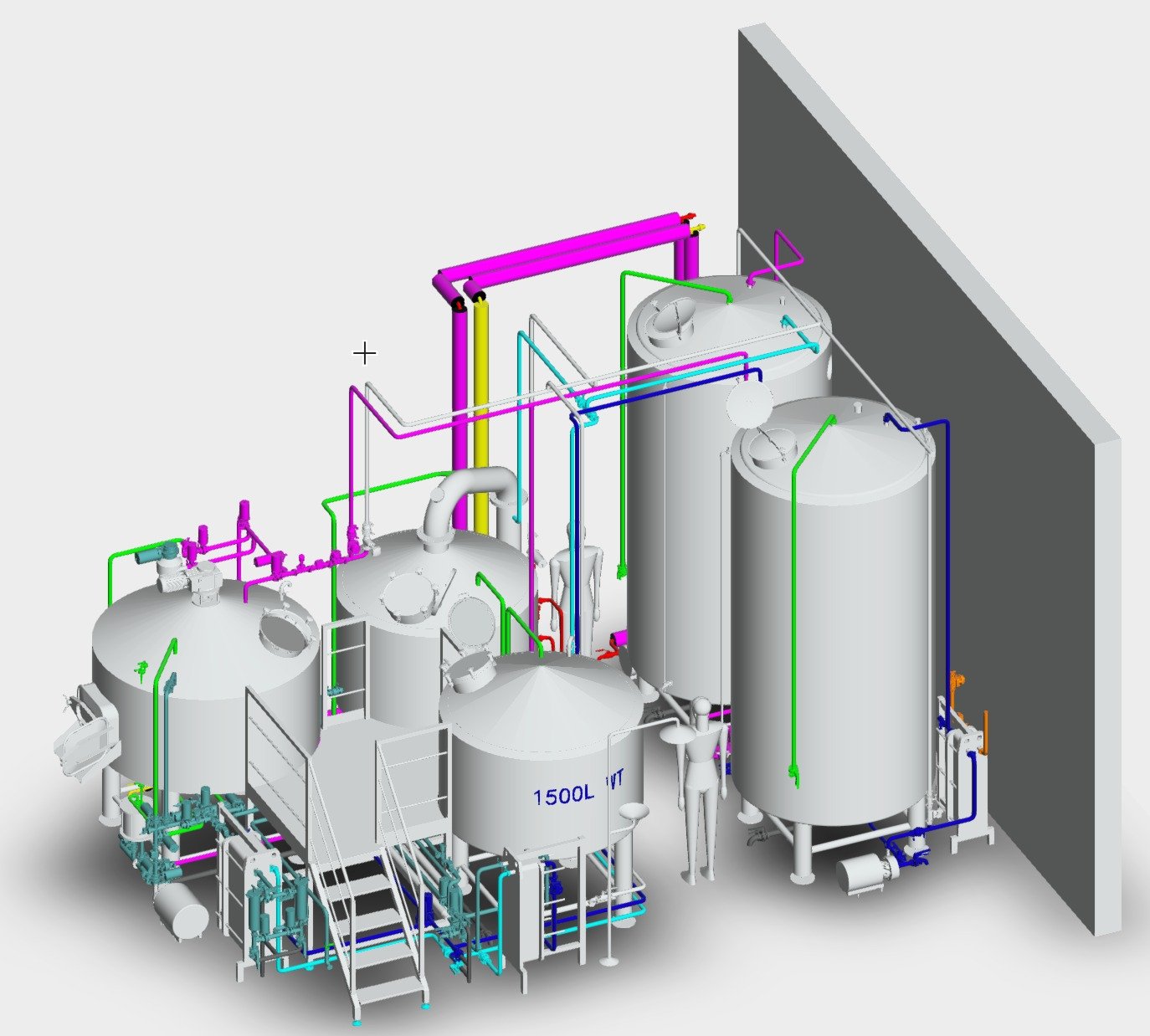

With all physical dimensions agreed, we create sophisticated sketches that show every single component in detail, and then insert every element into a CAD programme that allows us to explore every aspect of your brewery with you. This is put to scale within a layout of your site, the result being an extremely accurate representation of what your brewery is going to look like.

Once agreed, these drawings are the blueprint for the fabrication team. We produce our equipment to the highest professional standards. From the steel used, to the standard of the welds and polishing. You expect the best for your business, and so do we.

Installation is all about preparation. We work with you and contractors to ensure all utilities are in place ahead of time, and produce a pre-installation checklist so the team know what to have ready, such as forklifts, trucks, and cranes.

A member of BrewStar Systems will oversee the delivery and offloading at your site. From there, it becomes a quick “plug and play” process.

You might notice our installation and commissioning costs are much lower than our competitors. That’s because we believe your funds should be spent on the quality of the equipment, not on additional labour time when we can offset that with proper design and production methods.

Brand, Experience & Aesthetics

As important as your beer and your brand is, how your brewery is presented is also a key to your sucess.

For a brewery business built around attracting large on-site customer footfall, the aesthetics of your brewery design needs to be balanced with the daily workflow of your operational activities.

Even a brewery built for predominantly on-trade sales routes will need to consider how their brand and brewery image is presented at their place of production, for tours, for tastings, for company culture.

So when we sit down to design a successful brewery, we consider all aspects of how your brewery is experienced by both your staff and your prospective customers.

What tanks do we want visible? Where is the branding projected? Can the tanks or pipework be made to enhance the visual appeal if practical to do so? What flooring material is most suitable to the aesthetics? Where is the most produciton traffic? What are the options for storage of manufacturing materials? And so on.